No Products in the Cart

The Guggenhein Secret

3 components working together to create the most extraordinary cut you've experienced.

1.

Edge

A cut is created when two edges collide.

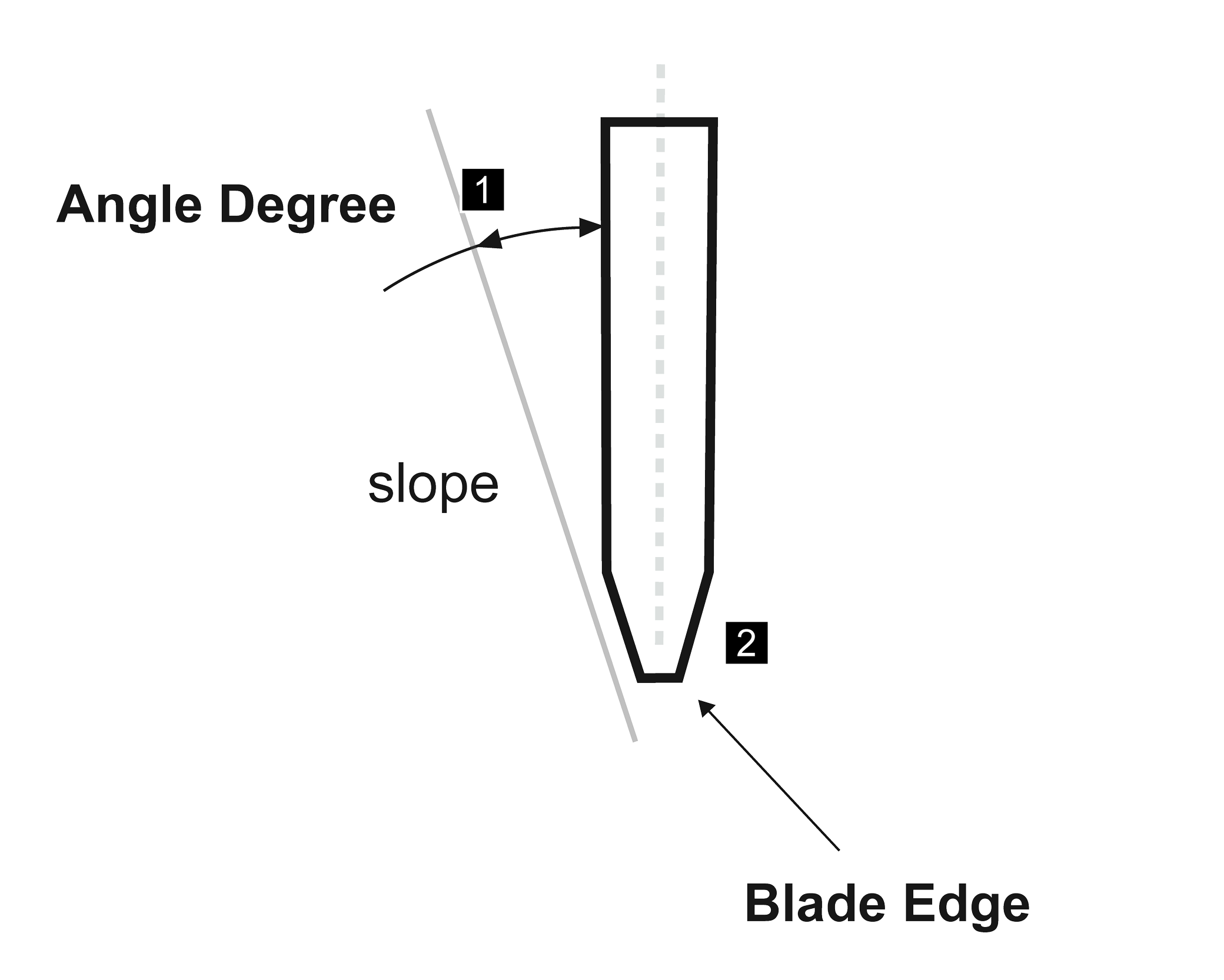

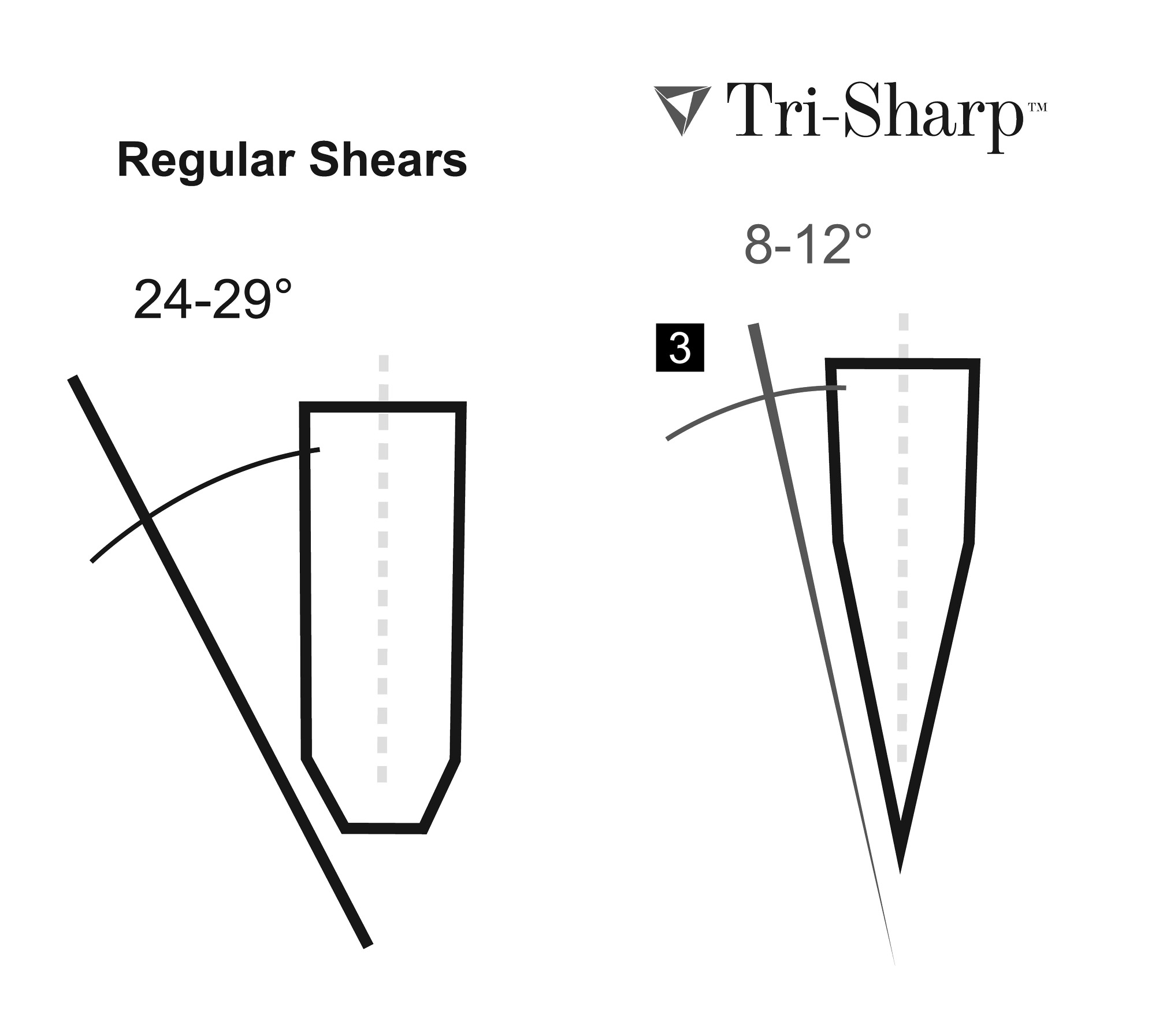

The smoothness of the cut, or sharpness, is determined by the angle degree¹ (slope) of each blade edge².

The lower the angle, the sharper the blade edge.

Each Guggenhein blade is meticulously sharpened (using special machinery) to an incredibly low 8 - 12 degree angle³.

This level of sharpness creates an extraordinarily smooth cut.

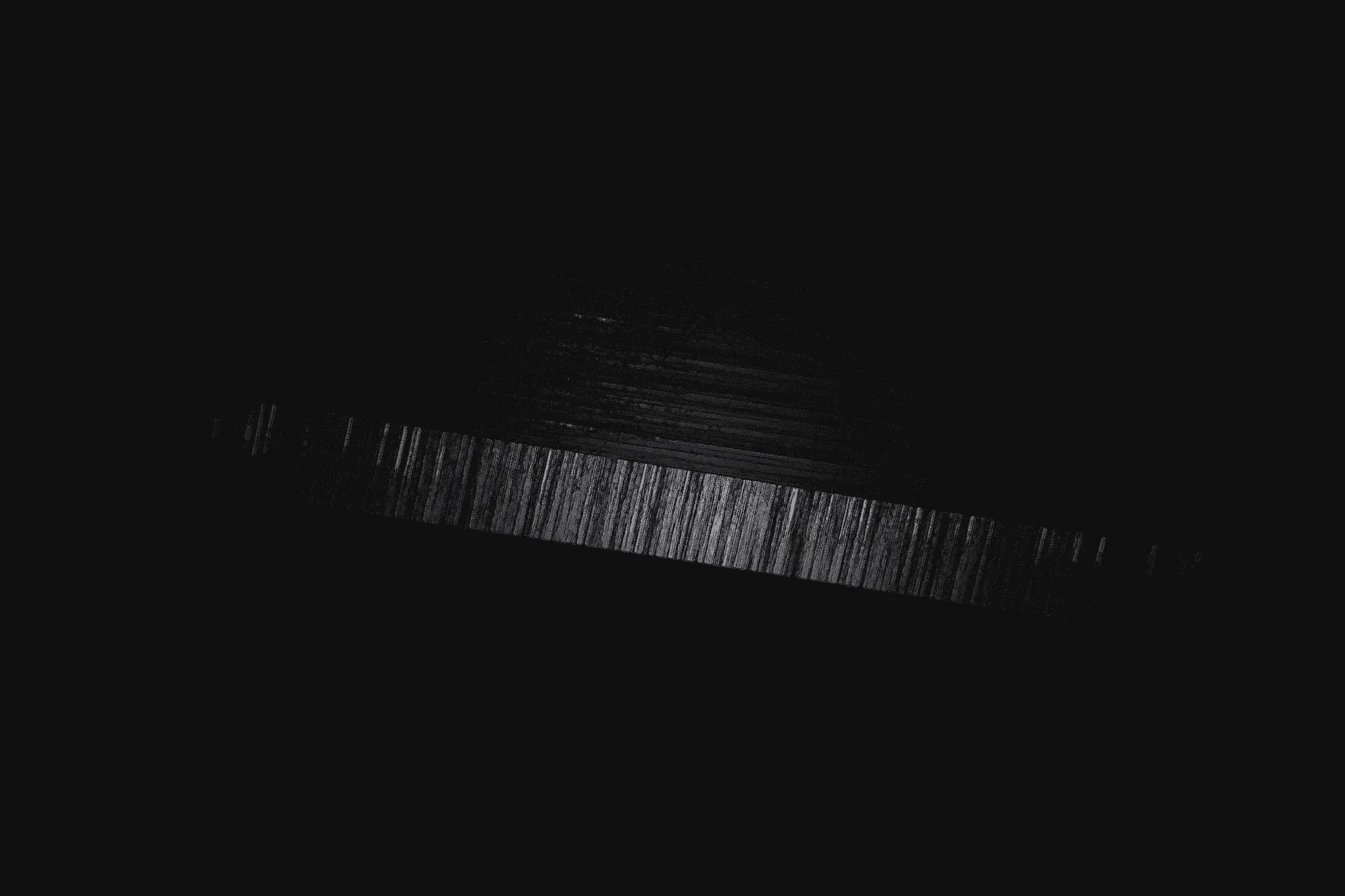

* Extreme close-up of a Guggenhein blade edge

2.

Steel

A sharp blade edge that does not consist of high quality steel, will dull quickly.

Steel quality is measured by how hard, or concentrated the steel is using the Rockwell Hardness Scale (HRC).

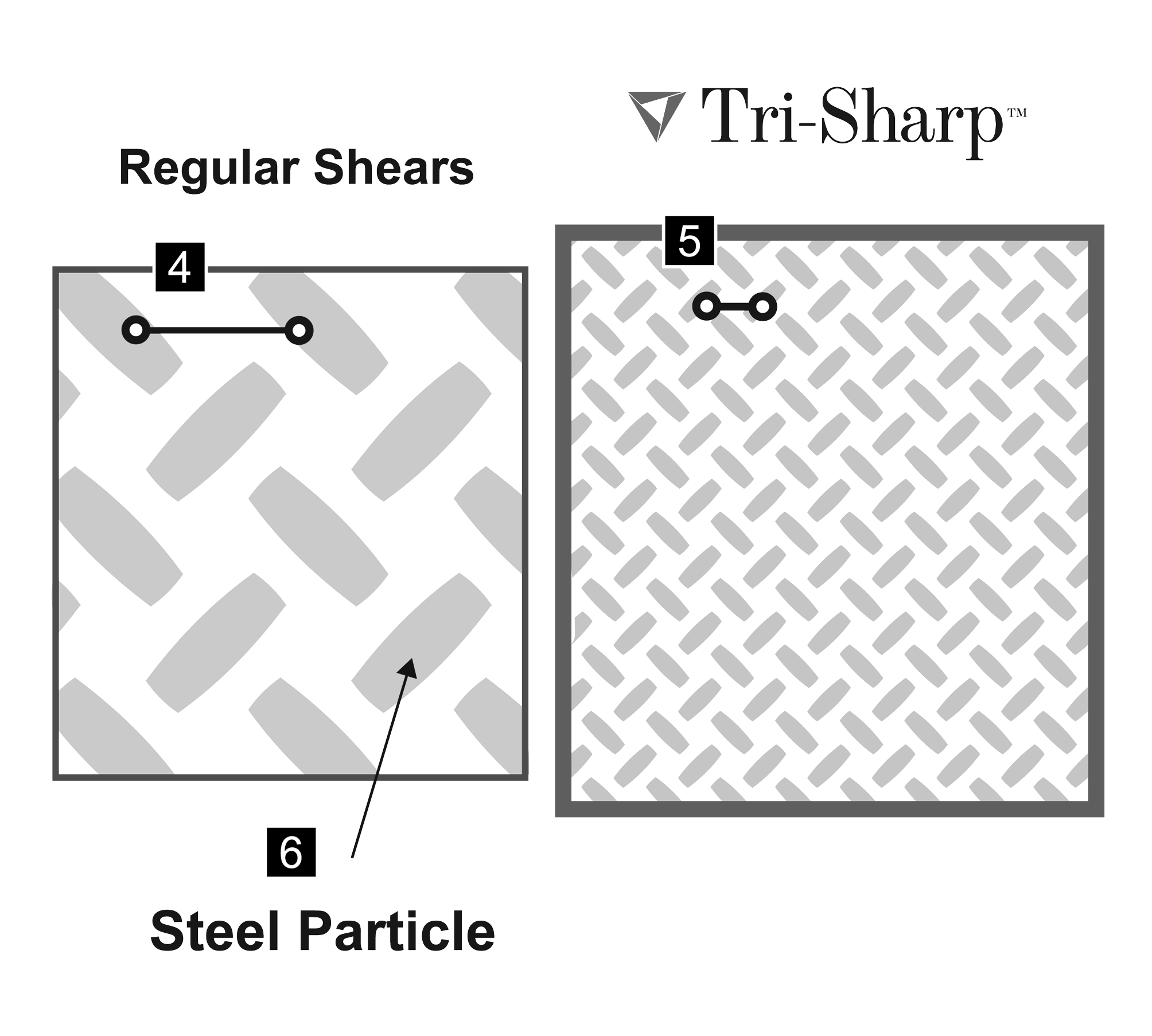

How far⁴ or close⁵ the steel particles⁶ are to each other determines quality/hardness:

A Guggenhein consists of a special steel that has superior hardness, scoring just below 60 HRC.

This hardness creates a strong foundation that allows the sharp edge to last.

3.

Leverage

You now have an extremely sharp edge, an incredibly hard steel to make that edge last,

the third and final component that completes Tri-Sharp™ is leverage⁷.

A Guggenhein's bolt (axis), is strategically placed (just past the half way point of the shears.)

This, combined with an additional weight added to the front half of the shears,

creates powerful leverage that further enhances an already smooth cut while taking pressure off your wrists.